Portfolio Selection

Analysis of the efficiency of the polymerization Process

The goal was to measure the quantity of residual non-polymerized monomer in the final product after the polymerization process.

To solve this problem, we developed both a method and a measuring instrument.

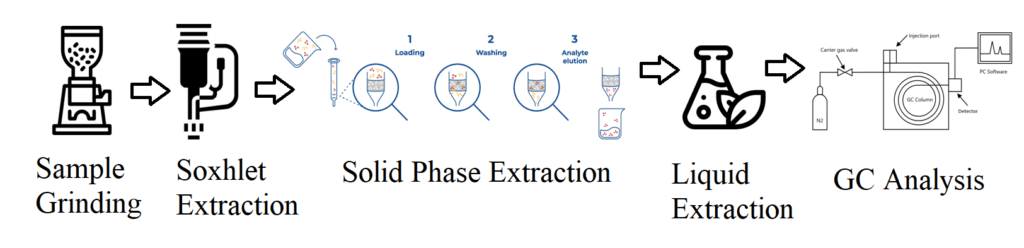

Method: The final polymerized product was subjected to a Soxhlet extraction procedure to dissolve everything in a strong solvent. This process results in a very complex matrix: in addition to the substance of interest, many other substances are present. To isolate the substance of interest, we developed a procedure based on the target substance’s properties: a solid-phase extraction, followed by a liquid-extraction. This final liquid-liquid extraction also had the role of concentrating the solution, thereby lowering the detection limit.

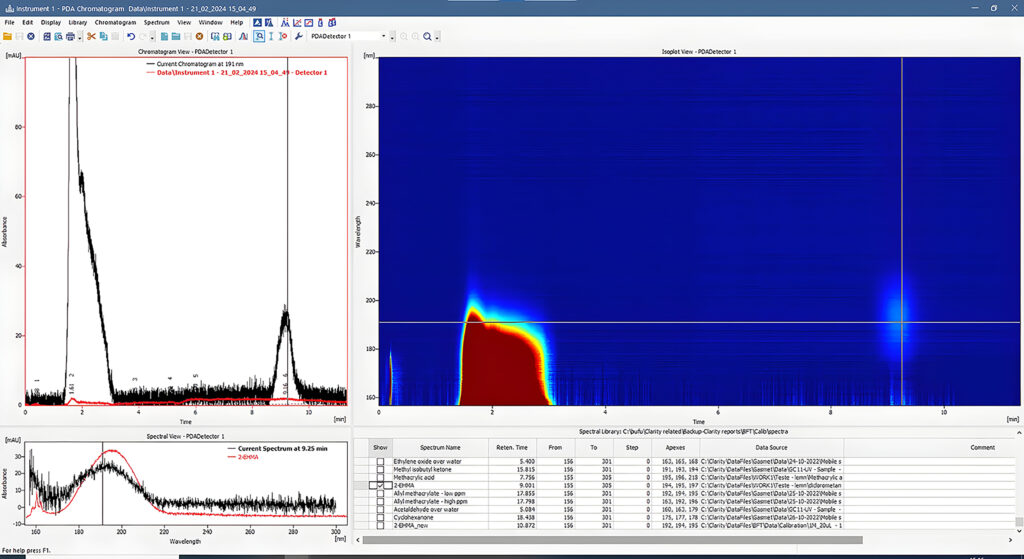

Instrument: As a measuring instrument, we developed a GC-UV system (gas chromatograph with UV detector). This has the advantage of positively confirming the identified substances (based on their UV absorption spectrum). The obtained liquid solution was injected into the system, and the result was compared with the injection of control samples (standards). Thus, the presence and quantity of residual monomer could be determined.

UV Gas Chromatograph - Chilled Capillary

Liquid sampling gas chromatograph with UV detector and chilled capillary column.

Sample preparation for trace monomer analysis using solid phase extraction (SPE).

Gas chromatograph

Gas chromatograph for liquid injection with UV detector and packed column.

Measurement

3D chromatogram with UV spectrum showing trace monomer analysis.

Reach out

Ready to embark on a journey of collaboration ?

Join us in shaping the future of technology and scientific discovery. Let’s work together to create custom solutions that drive progress and inspire breakthroughs.

Custom solutions, limitless discoveries